High-Performance Plastics Manufacturer

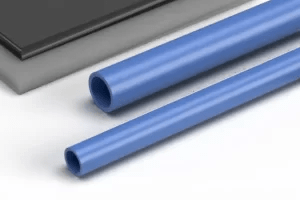

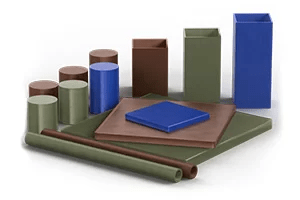

Plastic sheet, rod, tube, films, tapes, adhesives, sealants, and prototyping materials delivered to your location. Need something custom? Contact us to get the process started.

From Virgin PTFE to UHMWPE GOLD and every plastic in between; browse by material series, type, and fillers.

Filter our material library by common industries. Find what you need quickly by spec or industry.

Have a custom order ready? Are you looking for a custom fill rate or modified material?

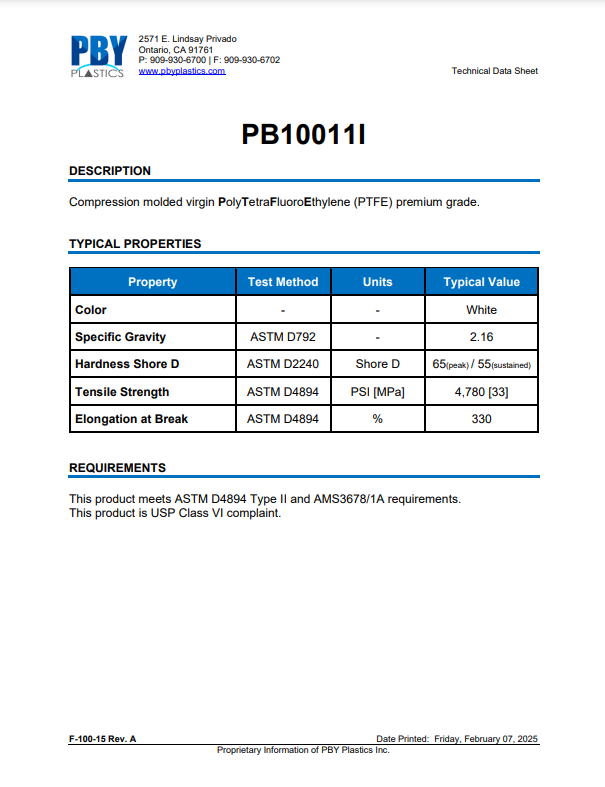

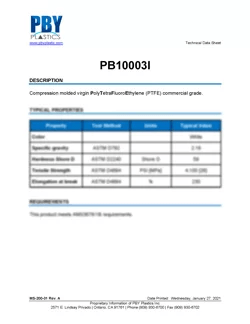

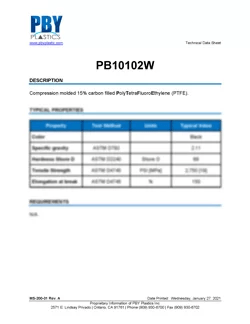

Access Plastic Material Data Sheets

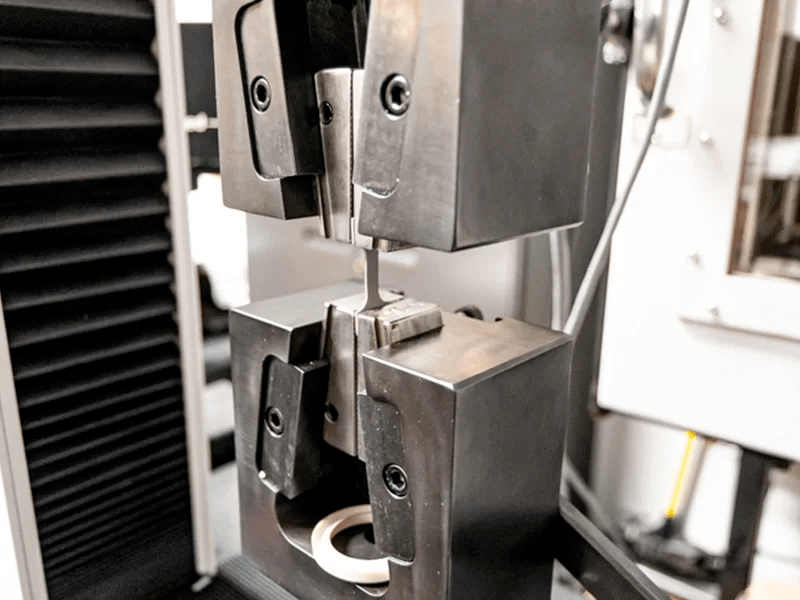

With in-house testing, you can be assured that your material order is meeting ASTM, MIL, and/or AMS standards. We've published our data in easy to digest PDFs for your design and purchasing teams.

Our Resin Suppliers

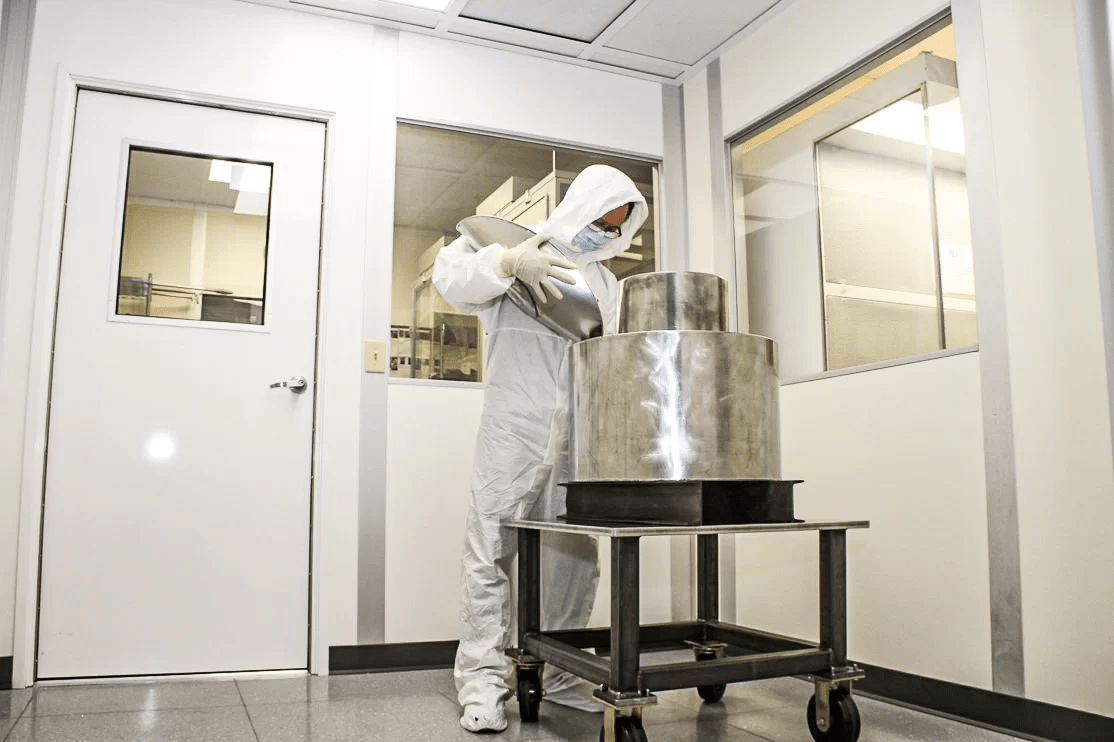

Tour Our Plastic Molding Manufacturing Facility

Learn more about our facility and our capabilities in providing high-performance plastics and materials. Our facility is equipped to solve your specific material needs.

Reduce Overhead with Performance Plastic Near Net Shapes

Our near net shapes offer many competitive advantages in plastics parts manufacturing. A base shape allows less scrap, improves efficiency, and reduces the cost of finished parts.

The Industry-Leading Plastic Manufacturing Company

We take pride in our wide selection of quality high-performance materials. All of the materials we offer are manufactured from the highest quality resin suppliers and can be delivered to you within 1-2 working weeks.