- Our Materials

- PB10000 Materials

- Carbon

PB10000 SERIES

Carbon-Filled PTFE

Carbon reduces creep, increases hardness, and elevates the thermal conductivity of parts. Carbon-filled PTFE materials have some electrical conductivity. Wear resistance can be improved by adding graphite.

PBY Material Codes:

PB10102 - 15% Carbon-Filled PTFE

Carbon-Filled PTFE Spec. Summary

| Property | Test Method | Units | 15 CARBON |

|---|---|---|---|

| Color | - | - | Black |

| Specific Gravity | ASTM D792 | - | 2.07 - 2.15 |

| Hardness Shore D | ASTM D2240 | - | 63 - 73 |

| Tensile Strength, min. | ASTM D4745 | PSI [MPa] | 2,400 [16.5] |

| Elongation at Break, min. | ASTM D4745 | % | 105 |

| Second Melt Peak Temp. | ASTM D3418 | °F [°C] | 621 [327] |

| Glass Transition Temp. | ASTM D3418 | °F [°C] | -143 [-97]; 246 [119] |

Material Available In:

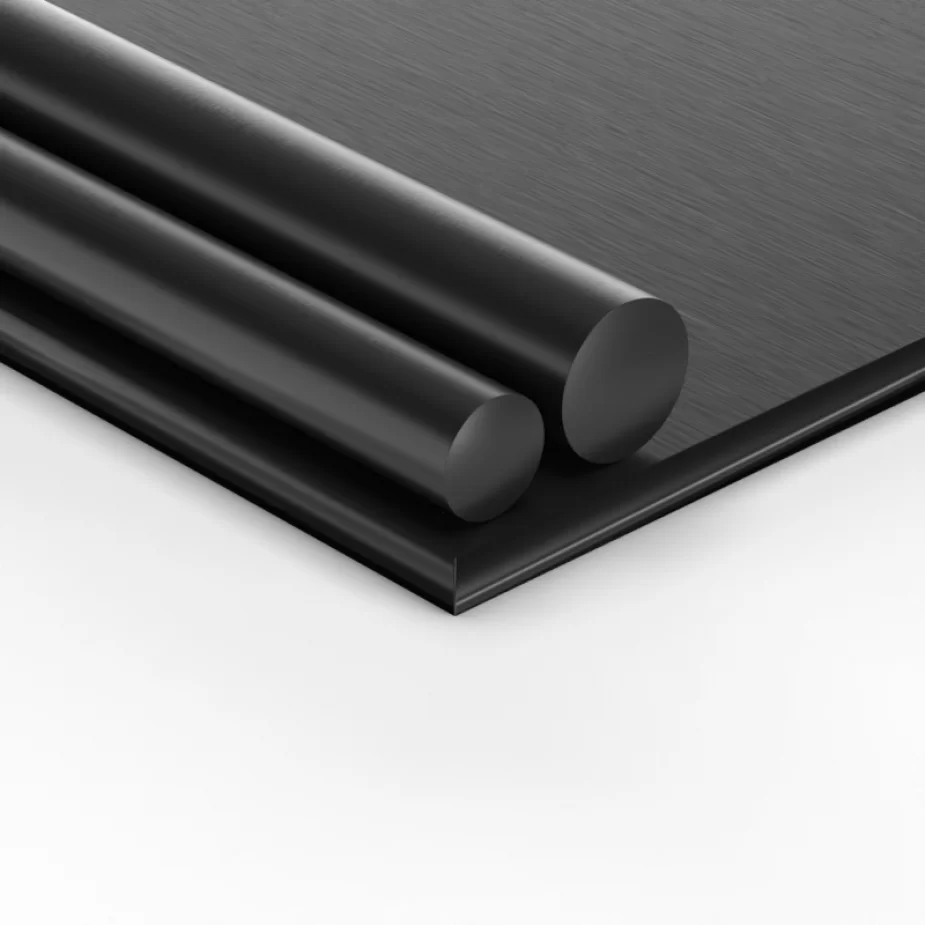

Carbon-Filled PTFE Rods

Carbon-Filled PTFE Tubes

Carbon-Filled PTFE Sheets

Carbon-Filled PTFE Material Properties

-

Good electrical and thermal conductivity

-

Good chemical resistance

-

Economical

-

Low Elongation

Typical Applications for Carbon-Filled PTFE

-

Bearings and Bushings

-

Electrical Components

-

Gaskets

-

Pump & Valve Components

-

Seals

-

Valve Seats

-

Wear Pads

Carbon-Filled PTFE Requirements

N/A

Carbon-Filled PTFE Material Data Sheet Downloads

PB10102 - Material Data Sheet

References

- Wypych, George. Handbook of Polymers. 2nd Ed., ChemTec/Publishing, 2016.

- Ebnesjjad, Sina. Fluoroplastics Vol1 & Vol2. 2nd Ed., Elsevier Inc., 2015.

- Aerospace Materials Specifications for PTFE materials (AMS3678)

- American Society for Testing and Materials (ASTM) Standards