- Our Materials

- PB10000 Materials

- Carbon Fiber

PB10000 SERIES

Carbon Fiber-Filled PTFE

Carbon fiber raises hardness, lowers creep, and increases compressive and flexural modulus. The advantage of using Carbon fiber instead of glass fiber is that Carbon fiber is inert to HF and strong bases.

Carbon fiber-filled PTFE materials have higher thermal conductivity and a lower coefficient of friction than their glass fiber counterparts. Carbon fiber-filled PTFE materials have a long wear life and excellent extrusion resistance. As their glass fiber equivalents, carbon fiber-filled PTFE materials are used in seal components for static and dynamic application and against chromium plate and steel.

PBY Material Codes:

PB10203 - 15% Carbon Fiber-Filled PTFE

Carbon Fiber-Filled PTFE Spec Summary

| Property | Test Method | Units | 15 CARBON FIBER |

|---|---|---|---|

| Color | - | - | Black |

| Specific Gravity | ASTM D792 | - | 2.00 - 2.050 |

| Hardness Shore D | ASTM D2240 | - | 62 - 72 |

| Tensile Strength, min. | ASTM D4745 | PSI [MPa] | 2,800 [19.3] |

| Elongation at Break, min. | ASTM D4745 | % | 190 |

| Second Melt Peak Temp. | ASTM D3418 | °F [°C] | 621 [327] |

| Glass Transition Temp. | ASTM D3418 | °F [°C] | -143 [-97]; 246 [119] |

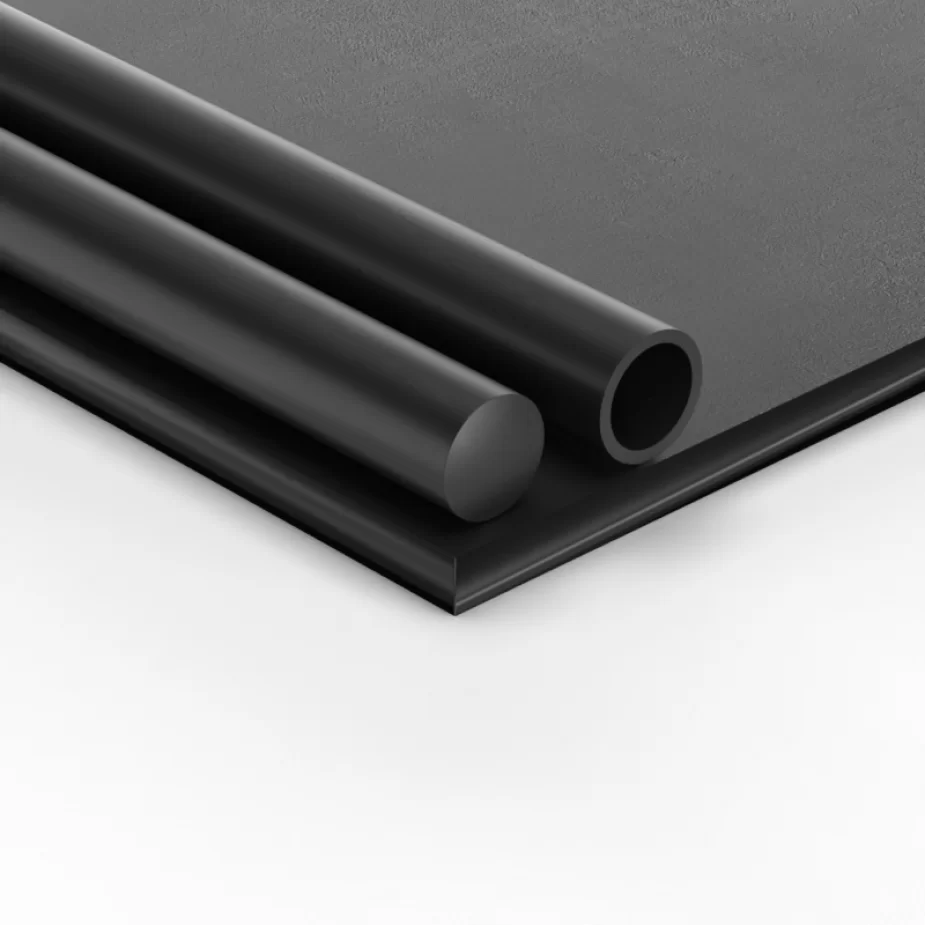

Material Available In:

Carbon Fiber-Filled PTFE Rods

Carbon Fiber-Filled PTFE Tubes

Carbon Fiber-Filled PTFE Sheets

Carbon Fiber-Filled PTFE Material Properties

-

Improved Compression and Wear Resistance

-

Excellent Chemical Resistance

-

High Strength Properties

Typical Applications for Carbon Fiber-Filled PTFE Plastics

-

15 % carbon fibers filled PTFE sheets are used in dynamic seal applications with rotating and alternating movements.

-

It is thoroughly used in seals that require a high-pressure resistance to wear. (Piston Rings for unlubricated compressors and bearing).

Carbon Fiber-Filled PTFE Requirements

This product meets AMS3678/10 requirements.

Carbon Fiber-Filled PTFE Material Data Sheet Downloads

PB10203 - Material Data Sheet

Carbon Fiber-Filled PTFE Spec. Compliance

References

- Wypych, George. Handbook of Polymers. 2nd Ed., ChemTec/Publishing, 2016.

- Ebnesjjad, Sina. Fluoroplastics Vol1 & Vol2. 2nd Ed., Elsevier Inc., 2015.

- Aerospace Materials Specifications for PTFE materials (AMS3678)

- American Society for Testing and Materials (ASTM) Standards