- Our Materials

- PB10000 Materials

- Polyimide

PB10000 SERIES

Polyimide-Filled PTFE

Polyimide is resistant to higher temperatures than aromatic polyesters. Even in dry environments, polyimide-filled PTFE materials will not abrade mating surfaces.

Polyimide-filled PTFE materials have low wear rates and low coefficient of friction, and they are used in seal components for static and dynamic applications where resistance to high pressure and temperature is key.

Polyimide-filled PTFE materials are excellent for dry running compressor rings.

PBY Material Codes:

PB10704 - 10% Polyimide-Filled PTFE

PB10706 - 15% Polyimide-Filled PTFE

Polyimide-Filled PTFE Spec. Summary

| Property | Test Method | Units | 10 Polyimide | 15 Polyimide |

|---|---|---|---|---|

| Color | - | - | Dark Yellow | Dark Yellow |

| Specific Gravity | ASTM D792 | - | 1.960 - 2.070 | 1.850 - 1.940 |

| Hardness Shore D | ASTM D2240 | - | 57 - 67 | 56 - 66 |

| Tensile Strength, min. | ASTM D4745 | PSI [MPa] | 2,300 [15.9] | 2,400 [16.5] |

| Elongation at Break, min. | ASTM D4745 | % | 200 | 180 |

| Second Melt Peak Temp. | ASTM D3418 | °F [°C] | 621 [327] | 621 [327] |

| Glass Transition Temp. | ASTM D3418 | °F [°C] | -143 [-97]; 246 [119] | -143 [-97]; 246 [119] |

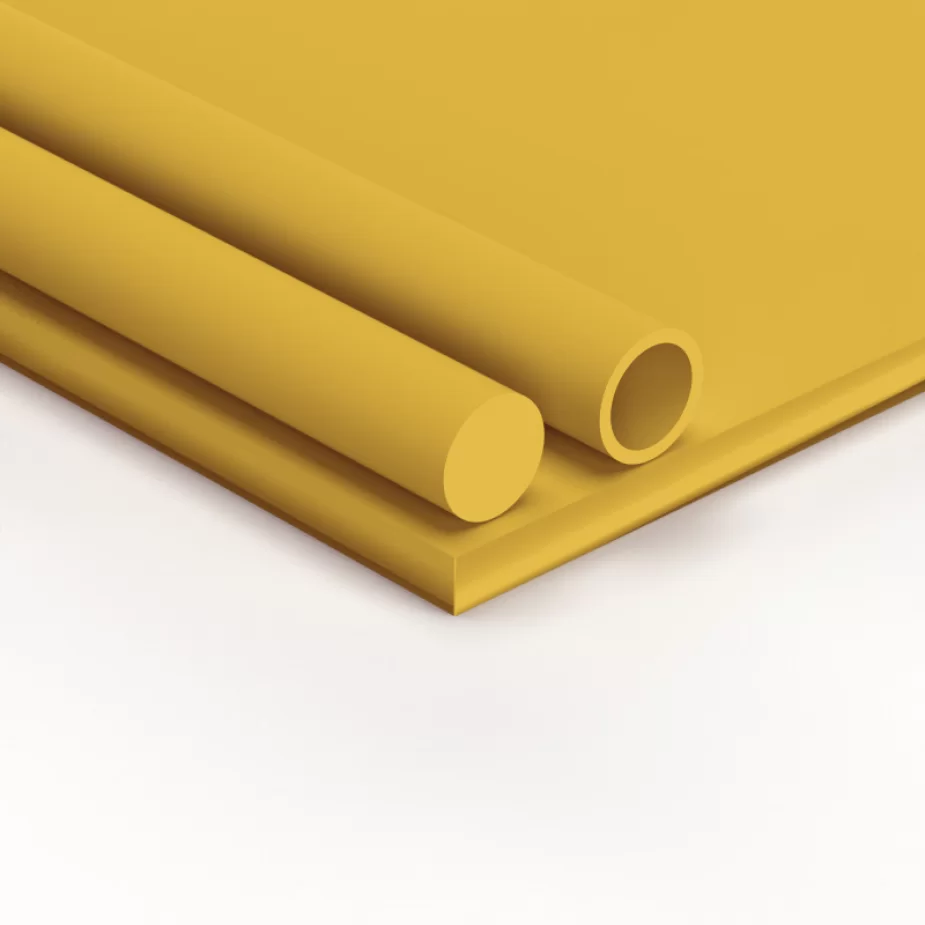

Material Available In:

Polyimide-Filled PTFE Rods

Polyimide-Filled PTFE Tubes

Polyimide-Filled PTFE Sheets

Polyimide-Filled PTFE Material Properties

-

Excellent high temperature resistance

-

Excellent high-pressure resistance

-

Very low friction coefficient

-

Increased hardness

Typical Applications for Polyimide-Filled PTFE

-

High temperature and high pressure

-

Dry running compressor rings

Polyimide-Filled PTFE Requirements

PB10704 meets AMS 3678/13 requirements.

PB10706 meets AMS 3678/16 requirements.

Polyimide-Filled PTFE Material Data Sheet Downloads

PB10704 - Material Data Sheets

PB10706 - Material Data Sheets

Polyimide-Filled PTFE Spec. Compliance

References

- Wypych, George. Handbook of Polymers. 2nd Ed., ChemTec/Publishing, 2016.

- Ebnesjjad, Sina. Fluoroplastics Vol1 & Vol2. 2nd Ed., Elsevier Inc., 2015.

- Aerospace Materials Specifications for PTFE materials (AMS3678)

- American Society for Testing and Materials (ASTM) Standards