Choosing Virgin Modified PTFE: Key Benefits Over Standard PTFE

PolyTetraFluoroEthylene (PTFE) is widely used in a variety of industries such as automotive, gas and oil, cryogenics, LNG, medical, food, beverages, and pharmaceutical to name a few, because of its outstanding properties. However, small modifications of the PTFE backbone structure at the molecular level have brought us a new industrial material known as modified PTFE (mPTFE). Altering the structure of conventional PTFE by adding a small percentage (≤ 1%) of a modifier, usually a perfluoropropyl vinyl ether (PPVE), allows modified PTFE retain the great properties of its precursor at the same time other properties of interest are enhanced.

Distinguishing Features of Modified PTFE: Density, Permeability, and Dielectric Strength

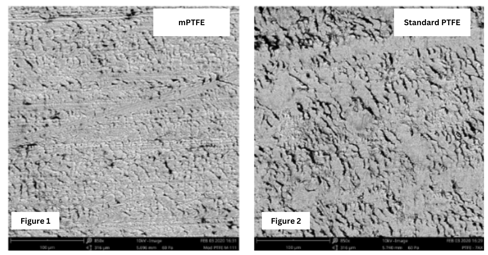

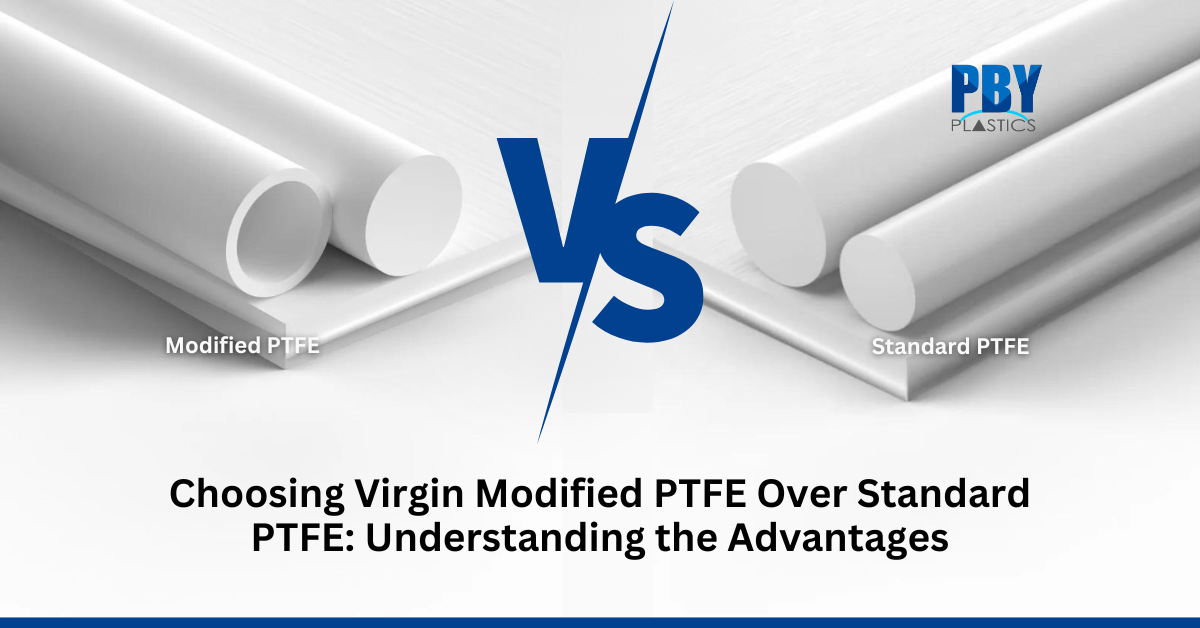

Modified PTFE is a denser material than PTFE. Its lower porosity is responsible for its lower permeability and improved dielectric strength properties, as well as for its smoother surface finish (see Figure 1). Higher resistance to permeation of modified PTFE is key in seal applications for gaseous and wet environments. The better high-voltage dielectric strength of modified PTFE is key in critical electrical applications where good insulation is required. Moreover, smooth surface finish is important in wear resistance applications.

Enhanced Mechanical Properties of Modified PTFE: Strength, Toughness, and Creep Resistance

Modified PTFE is stiffer (higher Modulus), stronger (higher strength), tougher (higher ability to absorb energy up until fracture), more ductile (higher elongation at break) than PTFE, and also, more resistant to deformation under load. In fact, the small presence of PPVE in modified PTFE is enough to inhibit crystallization and ensure homogeneous distribution of the crystallites in the amorphous matrix, such that mechanical properties are enhanced and cold flow is greatly reduced. Modified PTFE is a better material choice than standard PTFE when creep resistance is desirable.

Key Properties and Advantages of Modified PTFE

- Enhanced Mechanical Properties: mPTFE is denser, stiffer, and stronger than standard PTFE, making it more resistant to deformation under load.

- Improved Dielectric Strength: Ideal for electrical applications requiring insulation, mPTFE offers higher resistance to high-voltage currents.

- Superior Surface Finish: With a smoother and less porous surface, mPTFE is better suited for wear resistance applications.

- Lower Permeability: Its lower porosity makes it an excellent choice for sealing applications in gaseous and wet environments.

- Increased Creep Resistance: The presence of PPVE in mPTFE inhibits crystallization, enhancing its creep resistance.

Comparative Analysis of Surface Finishes: Modified PTFE vs. Standard PTFE

Machined modified PTFE (Figure 1) has lower surface roughness than machined PTFE (Figure 2) as shown in the SEM Images below, both taken under the same conditions and same magnification. Scale-like morphology and interrupted striations, typical of PTFE morphology after machining, are also visible on the machined surface of modified PTFE. However, features are much less pronounced and smoother, which makes Modified PTFE structure more compact and regular than the PTFE’s.