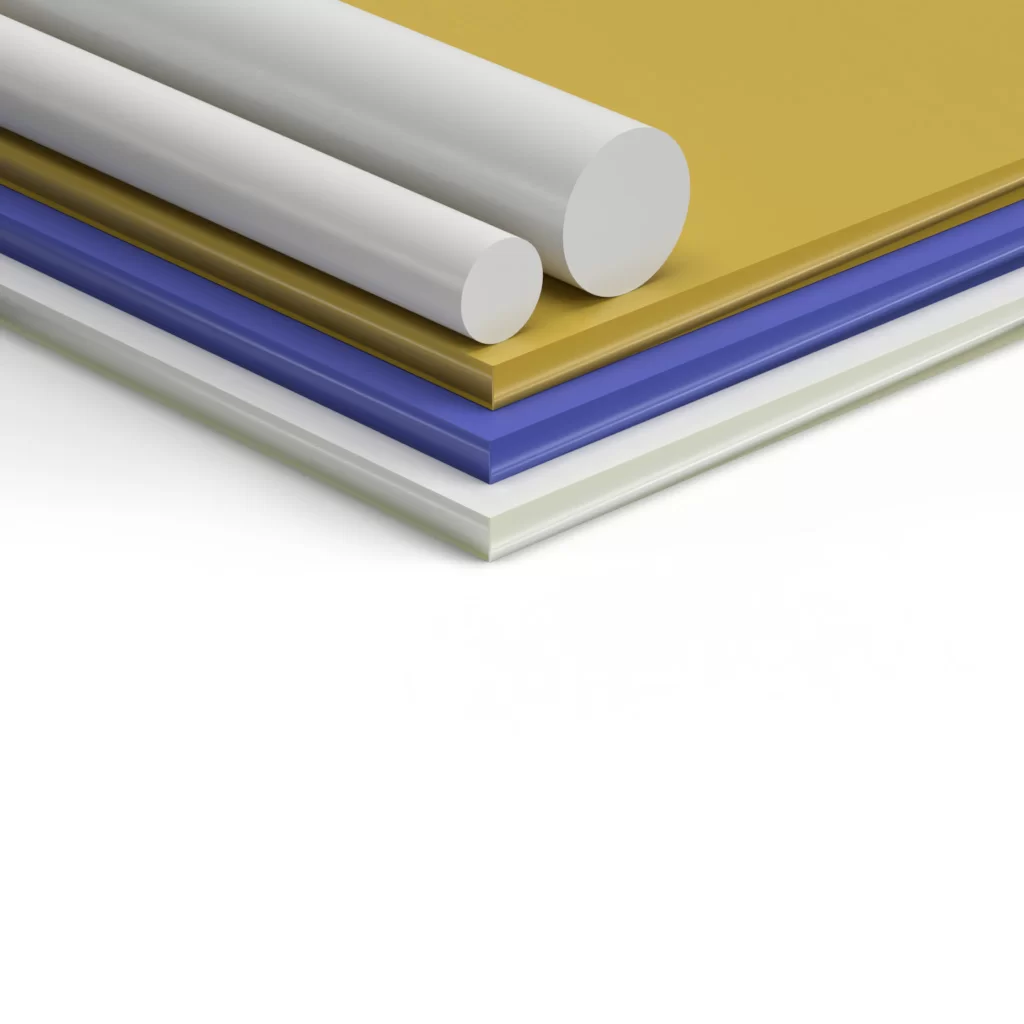

Understanding UHMWPE: Properties and Uses

When it comes to versatile polyethylene materials, UHMWPE (Ultra-High-Molecular-Weight Polyethylene) stands out as an exceptional material with a wide range of applications. However, not everyone is familiar with what UHMWPE is and the remarkable qualities it possesses. In this blog post, we will demystify UHMWPE material and delve into its key characteristics that make it a sought-after choice in various industries.

What Is UHMWPE Material?

UHMWPE, short for Ultra-High-Molecular-Weight Polyethylene, is a type of polyethylene with an extraordinarily high molecular weight. Its unique structure is characterized by long polymer chains, which provide remarkable properties that set it apart from conventional polyethylene materials.

Key Characteristics of UHMWPE Material

1. Exceptional Wear Resistance

One of the standout qualities of UHMWPE is its exceptional wear resistance. Its high molecular weight and long polymer chains make it highly resistant to abrasion, more so than PTFE, making it an ideal choice for applications involving sliding or high-friction components. Industries like material handling, automotive, and agriculture benefit greatly from its wear-resistant properties.

2. Low Coefficient of Friction

UHMWPE boasts a low coefficient of friction, even when unlubricated. This makes it a preferred material for applications where reduced friction is critical, such as conveyor belts, bushings, and bearings.

3. Chemical Resistance

3. Chemical Resistance

UHMWPE is highly resistant to a wide range of chemicals, acids, and bases, making it suitable for applications in corrosive environments like chemical processing plants and analytical equipment.

4. High Impact Strength

Despite its lightweight nature, UHMWPE is remarkably tough and has high impact strength. This characteristic makes it an excellent choice for applications where impact resistance is essential.

5. Excellent Machinability

UHMWPE is easy to machine and fabricate, making it a versatile material for various industries. Its machinability allows for precise and intricate designs, enhancing its suitability for custom components.

6. Self-Lubricating

Thanks to its low friction properties, UHMWPE is often considered self-lubricating. This means it can operate effectively without the need for external lubricants, reducing maintenance requirements.

Explore UHMWPE's Versatility

Now that you have a better understanding of what UHMWPE material is and its remarkable characteristics, it's time to explore its wide range of applications. Whether you're in material handling, food processing, agriculture, or any other industry, UHMWPE offers solutions that can improve your products and processes.

At PBY Plastics, we specialize in providing high-quality UHMWPE compression molded materials and products. Our team of experts can assist you in selecting the right UHMWPE material for your specific application needs.

In conclusion, UHMWPE material is a true engineering marvel, offering an impressive combination of properties that make it indispensable across various industries. Its abrasion resistance, low friction, chemical resistance, and machinability make it a versatile material for solving numerous engineering challenges.

Contact us today and let's explore the possibilities together. Whether you're looking to enhance product performance or innovate in your industry, UHMWPE could be the key to your success.